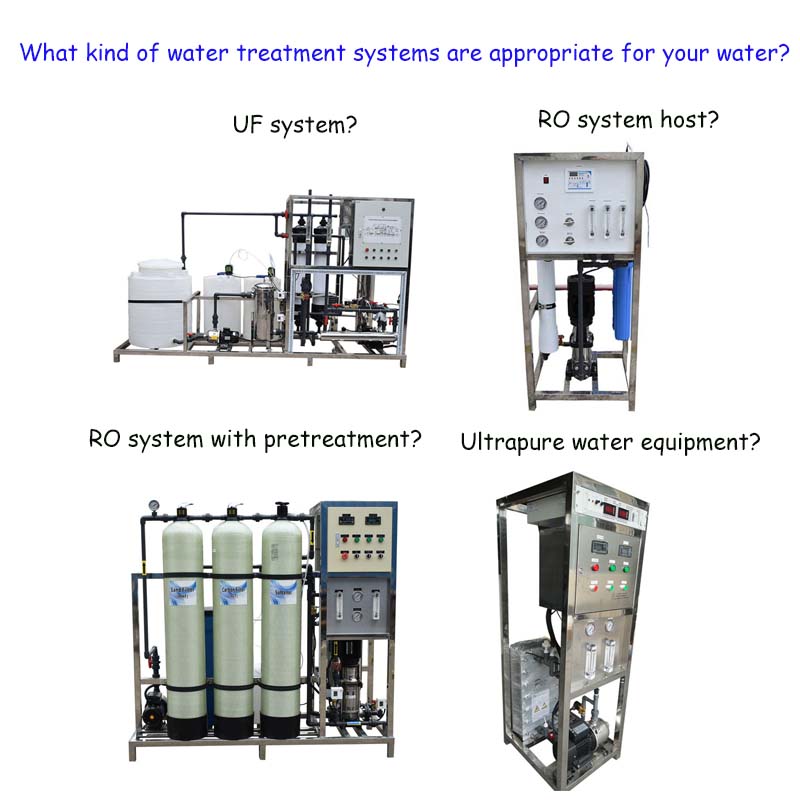

There are many types of water treatment systems, they have different types of processes and materials are different. The same type also has different specifications. Therefore, the classification of water treatment systems will be more complicated. Since the use of water runs through all aspects of our production and life, water treatment systems are used in a wide range of applications. The following is a brief introduction to the water treatment systems that is mainly used in daily life: pretreatment system, ultrafiltration equipment, reverse osmosis equipment, softener, high purity water equipment, etc.

Pretreatment system

There are 6 types of commonly used pretreatment systems: quartz sand filter, activated carbon filter, softener, multi-media filter, iron-manganese filter, fluorine removal filter.

1. Quartz sand filter: Filling quartz sand to absorb rust, mud sand and large particle impurities in water to reduce turbidity and ensure the effect of below filtration.

2. Activated carbon filter: Filling the activated carbon to absorb the colloid, organic matter, bleaching powder and other organic solvents in the water, to remove the odor and ensure the below filtration effect. Activated carbon can absorb the residual fluorine in the water, and There is obvious adsorption for the odor, colloid, pigment, heavy metal ions, etc. in the water . It mainly used for drinking water, pre-treatment of pure water, and reuse of water.

3. Softener: Filling the soft water resin to remove calcium and magnesium ions from the water and reduce the hardness of the water, so that it ensures the below filtration effect.

4. Multi-media filter (turbidity reduction): Using one or more filter media, or using one or several of the purified water filter materials to make high degree of turbidity or water containing impurities such as iron, manganese, fluorine, etc. through a certain thickness of granular or layered under a certain pressure Structure, it is effective in removing suspended impurities and purifying the water, thereby making the effluent water quality meet the use requirements. The main filter media are quartz sand, anthracite, manganese sand etc. It mainly used for soft water, pure water pretreatment, swimming pool or landscape water treatment.

5. Iron-manganese filter: This product is a special device for removing iron from groundwater. It is used to avoid the dangers of iron-containing water in life and industrial production.

6. Fluoride removal filter: It adopts TD removed fluorine filter material, which has the characteristics of fast adsorption speed and large capacity. It adopts special re-lifting agent to eliminate the problem of excessive aluminum ion and continuous regeneration, so that it can realize continuous water supply.

Ultrafiltration equipment

Ultrafiltration is a membrane separation technique (UItrafil-tration for short). The solution can be purified, separated or concentrated. Ultrafiltration is between microfiltration and nanofiltration, and there is no obvious boundary between the three. In general, ultrafiltration membranes have pore sizes between 0.05 um and 1 um and operating pressures of 0.1–0.5 Mpa. It is mainly used to intercept macromolecules such as suspended solids, colloids, particles, bacteria and viruses in water.

◆Ultrafiltration deep purification water system process: raw water → raw water pump → quartz sand filter → activated carbon filter → water softener → dosing device → precision filter → ultrafiltration membrane module → sterilization device → water production tank

Reverse osmosis equipment

Reverse osmosis pure water equipment:It effectively remove charged ions, inorganic substances, colloidal particles, bacteria and organic substances in water through RO membrane. Reverse osmosis pure water equipment is a new type of household and industrial water treatment systems, which has been favored by more and more consumers since its introduction. Pure water equipment uses the reverse osmosis technology of the United States. Its working principle is to exert a certain pressure on the water, so that the water molecules and the ionic mineral elements pass through the reverse osmosis membrane, thereby strictly separating the permeated pure water and the impenetrable bacterial virus. It can not only remove impurities, bacteria, viruses, etc. in the water, but also remove radioactive particles and heavy metals harmful to the human body.

Reverse osmosis system must have precision filter : filter out particles and bacteria above 0.2um in water to achieve high-precision filtration and ensure reverse osmosis membrane have enough long lifespan.

◆ Direct drinking water system process: raw water → raw water tank → raw water booster pump → multi-media filter → water softener → RO reverse osmosis unit → water storage tank → frequency converter → booster pump → disinfection system → water supply pipe network → water point

◆Brackish water desalination system process: raw water (brackish water) → raw water tank → pretreatment system → dosing device → high pressure pump → reverse osmosis membrane module → ultraviolet → ozone → water storage tank → purified water

Softened water equipment

The softened water equipment includes a softened water device of a scale inhibitor dosing device and a softened water device of a water softener.

The kettle that boils water will foul, which means that the water contains calcium and magnesium ions, which is considered to be high in hardness. At this time, the water softener will come in handy. The functional ions on the resin are exchanged with calcium and magnesium ions in the water to adsorb excess calcium and magnesium ions in the water to achieve the purpose of softening the water. Soft water equipment uses ion exchange to soften water, it completely remove scale and has a large amount of water. Soft water equipment cannot remove impurities, bacteria, viruses and heavy metals from water, and its role is to drive out water alkali. The use of soft water equipment can effectively reduce scale and increase the service life of water heaters. However, the water from the softener cannot be directly consumed, and more is used to soften domestic water, such as bathing, washing clothes, and beauty water.

◆Softened water system process: raw water → raw water tank → raw water booster pump → quartz sand filter → activated carbon filter → water softener → water storage tank → booster pump → water point

Ultrapure water equipment

Ultrapure water equipment can produce water conductivity up to 10-18.2 MΩ.CM. Therefore, it is widely used in the microelectronics industry, semiconductor industry, power generation industry, pharmaceutical industry and laboratories. It can also be used as pharmaceutical distilled water, food and beverage production water, boiler feed water for power plants, and other applications of high purity water. You could use advanced ultra-pure water equipment process such as pre-treatment + double-stage reverse osmosis + EDI process, it fully meets the ultra-pure water resistivity to ensure qualified water quality. Below are three other ultrapure water configuration procedures.

◆Electronic ultrapure water equipment using ion exchange:

Raw water → raw water pressure pump → multi-media filter → activated carbon filter → water softener → precision filter → cation resin filter bed → anion resin filter bed → cation and anion resin mixed bed → microporous filter → water point

◆Electronic ultrapure water equipment using two-stage reverse osmosis:

Raw water → raw water pressure pump → multi-media filter → activated carbon filter → water softener → precision filter → first-stage reverse osmosis → PH adjustment → intermediate water tank → second-stage reverse osmosis (reverse osmosis membrane surface with positive charge) → Purification water tank → pure water pump → microporous filter → water point

◆Electronic ultrapure water equipment using EDI method:

Raw water → raw water pressure pump → multi-media filter → activated carbon filter → water softener → precision filter → first-stage reverse osmosis machine → intermediate water tank → intermediate water pump → EDI system → microporous filter → water point

There are certain differences in the functions of different types of water purification equipment. When selecting equipment, it is necessary to pay attention to applicable and professional of equipment. For more information on water treatment systems, please visit https://ocpuritech.com/